Capability

Machine Details

- Hampson has state of art machine which can cater wide range of parts based on the complexity and critical tolerance level.

Machine and Equipment

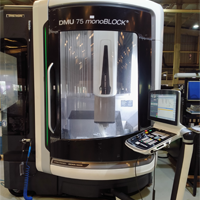

- DMG 75 Monoblack – 5 Axis Machine 1

- 5(4+1)-Axis Milling Machines 3

- 4-Axis Milling Machines (DMG & Brother ) 3

- CNC Turning Centres 20

- CNC Turn-Mill 5

- Grinding Machines (Cylindrical, Centreless, Surface) 3

- CMM (Carl-Zesis) 1

- Mahr Form Tester1

- Visual Measuring System1

- Profile Projector 2

- Electronic Comparator2

- Roundness Tester 1

- Hardness Tester1

- Roughness Tester1

- Lapping Machines 4

- Barrelling Machines3

- Ultra Sonic Washing Machines3

- Band Saw Machine1

NDT : NADCAP and Rolls Royce Approved facility for FPI, MPI and Ultrasonic Cleaning Special Process : Outsourced to NADCAP/OEMs approved suppliers

NDT

Hampson has NDT facility approved by NADCAP and Rolls-Royce

Tank Size: 350 X 500 X 500 MM

- FPI

- MPI

- Ultrasonic Cleaning

Engineering Capability

Hampson has dedicated skilled and experienced teams for Process engineering, Programming and new product development. Having core capability in precision machining of medium to complex jobs, we also have experience in sub-assemblies.

We use Delcam and Feature cam & Solid cam softwares for CNC Programming and simulation.

ZW cad, Auto cad and Solid Works are used for process documentation and modelling.

Raw Material handled: Alloy Steel, Stainless steel, PH steel, Nickel alloy, Cobalt alloy, Titanium, Molybdenum and Aluminum input in the form of Bars, Plates, Castings and forgings.

We outsource Special Process like Anodizing, Passivation, Electroless nickel plating and heat treatment to NADCAP/Customer approved facility.